What Are The Main Advantages Of Plc

Before PLC is introduced, Relays are used to control the process. This relay control panel is required regular maintenance, it consumed a lot more power, and even during the troubleshooting time, it requires a lot of effort to find the problem because there are lots of wire and it takes too much time to figure it out.

There are some advantages of PLC over Relay control system:

- PLC system is easier to install and maintain.

- Easy to program and modify the logic during offline as well as online.

- PLC system requires negligible maintenance.

- Easy troubleshooting, Saves a lot of time during troubleshooting.

- PLC has a fast operating time usually in milliseconds.

How Do You Handle A Client Who Pushes Back On The Automation Timeline For A Detailed Project

Automation engineershave to provide clear objectives and expectations to the clients they work for. The goal of this question is to understand how the candidate deals with conflict and realistic timelines. What to look for in an answer:

- Respectful resolution of conflict with any stakeholder

- Realistic timelines within project management

- Critical thinking and problem solving skills

Example:

“I first book a meeting with the client so that I can understand and empathise with their concerns about the timeline. I then explain the various parts of our project timeline so that the client can comprehend why we created the timeline this way. I also try to see if there is anything we can do to mitigate the client’s concerns without making unrealistic promises.”

When Leading An Automation Project How Do You Gain The Support Of Your Team

Depending on the role, you may require an automation engineer to lead a team of people. What to look for in an answer:

- Strong communication skills

- Refined interpersonal skills to bring a team together and lead them to success

- Willingness to take on a leadership role

Example:

“I have been the project manager on several high-profile projects, and I loved the challenge. To me, it is important to clearly define the goals of the project right from the beginning, so as I bring people into the project, they know immediately what their role is and how they contribute to the success of the project. Then I…”

Also Check: Administrative Assistant Questions To Ask Interviewer

What Is Field Bus

Fieldbus is a general term for a digital only, high speed communications protocol. The key attribute to Fieldbus communications is higher speed communications with the possibility of addressing multiple transmitters all on the same field wiring.

The Foundation Fieldbus is a specific digital protocol that is often shortened to just be called Fieldbus. Other digital only communications such as Profibus are also Fieldbus protocols

Coming Over To The Advantages Of Plc Programming

PLC is easier to troubleshoot. Additionally, controller programs can be developed offline, allowing you to test programs before installing them, avoiding costly mistakes. Finally, it makes it easy to monitor the inputs and outputs of multiple devices.

If you are having programming knowledge, then it will be very easy for you to understand the flow of the ladder logic diagram. This programming language is relatively simple and easy to understand for you.

Technology is ushering in a new era globally. Similarly, there are numerous advantages to employing a software-based PLC. It is critical to properly strategize in order to achieve your goal. We are confident that our efforts will help you ace your PLC interview and get the job of your dreams.

Stay updated with our newsletter, packed with Tutorials, Interview Questions, How-to’s, Tips & Tricks, Latest Trends & Updates, and more Straight to your inbox!

Don’t Miss: What Are The Top 10 Interview Questions

How You Check A Plc System

- Check that all cable connections between the PLC and the plant are complete, stable, and to the specification necessary to meet local standards.

- Checking that all the incoming power supply matches the voltage setting for which the PLC is set.

- Checking that all protective devices are set to their appropriate trip settings.

- Checking that emergency stop button work.

- Checking that all input/output devices are connected to the correct input/output points and providing the correct signals.

- Loading and testing the software.

Which Plc Programming Method Do You Prefer

The interviewer might ask this question to check your experience and expertise in using different programming styles to implement PLC programs. Frame the answer by specifying your preferred programming method and its advantages. You can also demonstrate your willingness to learn by mentioning that you are enthusiastic to try other programming styles if required for the job.

Example:”In my previous role at a petrochemical plant, our team used ladder diagrams to program our PLC systems. I prefer ladder diagrams for PLC programming as it supports online editing and comments, making it easy for all team members to follow the schema. I am also eager to try other programming methods like sequential function charts, instruction lists and function block diagrams to improve my skills in PLC programming.”

Recommended Reading: How To Get Better At Job Interviews

What Is The Purpose Of A Latch Coil

A latch coil instruction causes output to remain energized even if changes are stimulated by the status of the contacts which caused the output. If any rung path has continuity of logic, then this instruction turns the output ON and holds it ON, even if continuity of logic or device control is lost.

What Is Scan Time And Scan Cycle In Plc

Each PLC has a scan time and a scan cycle. This considers how fast PLC work.

The Scan cycle is the cycle of which the PLC sens the inputs, executes the PLC programs, and then updates the outputs. This will take some amount of time usually in milliseconds.

The amount of time it takes for the PLC to finish one complete cycle is called the scan time of PLC.

Also Check: How To Interview A Project Manager

What Is Encoder

A feedback device which converts mechanical motion into electronic signals. Usually an encoder is a rotary device that outputs digital pulses which correspond to incremental angular motion.

The encoder consists of a glass or metal wheel with alternating clear and opaque stripes that are detected by optical sensors to produce the digital outputs.

What Is An Hmi

HMI is a Human Machine Interface designed for industrial use. HMI systems can be called a window of a process. This window can be on a monitor or on special tools such as operator panels. An HMI system has connected an industrys hardware and software components so that the HMI can exchange user-system information.

You May Like: What Is Cloud Computing Interview Questions And Answers

What Is Ladder Diagram

This is a programming language, which expresses a program as a series of âcoilsâ and âcontactsâ, simulating the operation of electromechanical relays.

The resultant program is the equivalent of an equation, which is executed continuously in a combinatorial manner.

The advantage of this language is the familiarity many electricians have with the simple operation of relays.

Disadvantages include the complexity of large, cross-connected programs, and the difficulty of expressing such non-binary functions as motion control and analog I/O.

Where Do You See Our Company’s Biggest Opportunity For Improvement Regarding Our Automation Processes In Manufacturing

Candidates often research a company before an interview. The goal of this question is to determine what the candidate knows about the company. What to look for in an answer:

- Willingness to research the company before the interview

- Critical thinking skills

- Communication skills to present a perceived improvement

Example:

“When I was researching the company, I noticed that there seems to an opportunity to improve the efficiency of PLC programmeming and to streamline the process. The reason I suggest this is…”

Read Also: Sr Qa Engineer Interview Questions

Tips To Prepare For A Plc Technical Interview

Here are a few tips that you can use to prepare for an upcoming PLC interview:

-

Read the job description carefully. You can use it to identify if the position requires prior knowledge of specific concepts and topics and prepare for them accordingly.

-

Practise your answers with a friend. Reviewing and practising your answers with a colleague or friend helps to increase your confidence levels when interviewing.

-

Review PLC programming basics. Whether you use PLC regularly for work or if it has been several months, it can be helpful to review the basic concepts and programming constructs to update your knowledge.

Explain The Memory Structure In The Plc System

There are mainly four parts in the Siemens PLC memory:

- Load Memory User program is stored in the Load Memory

- Work Memory Store the executive part of the PLC program like a RAM in the computer.

- System Memory Store the addressing part of the PLC program like Inputs, Outputs, Timers, Counters, and Bit Memory.

- Retentive Memory Store the data permanently in this part of the memory.

You May Like: How To Crack Amazon Front End Developer Interview

+ Plc Interview Questions

Are you a fresher and searching for a job in the field of Automation, Instrumentation, Electrical? Then this article might be helpful for you to crack some of the interview questions related to PLC.

We are listing here some of the most popular and most asked interview questions of PLC based on our working experience in the field of Instrumentation.

No matter what if you are a fresher or experienced, this list will help you to add more value to your PLC knowledge.

So further not waste more time and Lets explore the list.

What Do You Know About Overload Safety Relays

Ans: Overload safety relays are specifically designed to offer the over-contemporary safety of electrical automobiles and circuits. These overload relays may be of various sorts together with constant bimetallic strip type, digital or interchangeable heater bimetallic.

The temperature of the motor winding may be predicted by the use of the motor armature thermal model digital overload safety relay via way of means of measuring motor contemporary. Thus, the motor may be correctly included in the use of an overload safety relay.

| Related Article: Hardware Design Development Interview Questions Advanced |

Read Also: Anne Rice Interview With The Vampire Tv Series

What Are The Inputs And Outputs In Plc

There are mainly two types of Inputs and Outputs in the PLC System

Digital Inputs/Outputs have only two-state. Whether it is ON or OFF. As a result, they only send/receive signals in the form of 0s or 1s to/from PLC system.

Digital IOs

Analog Inputs/Outputs are once they have more than two states. These devices send/receive complex signals to/from the PLC system which is in the form of Voltage or Current.

Analog IOs

What Is The Difference Between Plc And Dcs

Distributed Control System is a specially designed control system to manage complicated, giant, and geographically distributed control systems throughout the complete plant space.

In DCSs, multiple controllers are connected with each other via a high-speed communication link and use a central database. The components like Engineering Station, Operator Station, Process Control Unit, Communication Systems are used in DCS.

Programmable Logic Controller itself is a single controller, used to control a process. In general, SCADA is used for visualization. SCADA doesnt have a central database.

Also Check: How To Ace An Amazon Interview

How You Define Functional Block Programming

Data flow is the prime principle behind an FBD. In these types of programs the values pass through feature blocks from the inputs to the outputs.

A FBD program is designed using function blocks that are bound together to describe the exchange of data. The connecting lines will have a type of data that must be compatible on both ends.

What Is Sinking & Sourcing

The most brief definition of these two concepts would be:

SINKING = Common GND line

SOURCING = Common VCC line

- Sinking I/O circuits on the I/O modules receive current from sourcing field devices. Sinking output modules used for interfacing with electronic equipment.

- Sourcing I/O are the sourcing output modules used for interfacing with solenoids.

Don’t Miss: How To Answer Leadership Interview Questions

Top Plc Interview Questions

The Indeed Editorial Team comprises a diverse and talented team of writers, researchers and subject matter experts equipped with Indeed’s data and insights to deliver useful tips to help guide your career journey.

A programmable logic controller is a rugged electronic device that helps automate services across several industries. If you enjoy robotics, automation and technology, you might be interested in a career as a PLC technician or automation engineer. Reviewing popular interview questions and preparing answers can help you update your knowledge and gain confidence to attend an upcoming PLC interview. In this article, we review some of the popular PLC interview questions, discuss sample answers and share tips you can use as a guide while preparing for the interview.

What Type Of Licensing Patterns Used In The Scada Software

Typically two types of licenses are used in the SCADA software

- Dongle Key : It is a hardware lock which can be put on the communication port of the PC.

- Software Lock : Here the software code is the license. Typically you can put the code while installation or transfer the code from Floppy to hard-disk.

Also Check: Interview Questions For An Hr Manager

What Is Plc Scan

PLC Scan The PLC program is executed as part of a repeat process called a scan. A PLC scan ends when the CPU reads input status. Next, you execute the application programme. The CPU then performs internal communication and diagnostic functions. Eventually, the performance status is changed by the CPU. This process repeats in run mode as long as the CPU.

The time required to complete a scan depends on the size of the program, the number of I/Os, and the amount of communication required.

How Could You Take A Look At One Plc Device

Ans:

Don’t Miss: How To Get Over Interview Anxiety

Top 100+ Industrial Automation Engineer Interview Questions And Answers

Question 1. What Is Automation?

Answer :

Automation is delegation of human control capabilities to technical equipment for increasing productiveness, better great, reduced price & expanded in protection running conditions.

Question 2. What Are The Different Components Used In Automation?

Answer :

The components of automation device consist of

Sensors for sensing the input parameters Transmitters for transmitting the raw sign in electrical formControl gadget which incorporates PLC, DCS & PID controllersOutput gadgets / actuators like drives, manage valves.Electrical and Electronics Engineering Interview QuestionsQuestion 3. What Are The Different Control Systems Used In Automation?

Answer :

PID Controller based control gadgetPLC based manage systemDCS based totally Control gadgetPC Based automation systemQuestion four. Explain Pid Based Control System?

Answer :

PID is the algorithm widely utilized in closed loop control. The PID controller takes care of closed loop manipulate in plant. A number of PID controller with single or a couple of loop can be taken on network.

PID Controllers are broadly for independent loops. Although some good judgment may be applied however now not a whole lot of sequential common sense may be carried out in PIDs.

Industrial Relations Management TutorialQuestion 5. Difference Between Plc & Relay ?

Answer :

Answer :

DCS is often used inside the massive flowers where the redundancy stage needed is more and the analog enter used are excessive.

What’s The Position Of I/o Modules In Plc

Ans: I/O modules are used to offer I/O signs withinside the shape of easy on and stale commands in PLC, such that an enter module detects the reputation of entering alerts together with push-buttons, switches, temperature sensors, and so on while an output module controls gadgets together with relays, motor starters, lights, and so on.

Read Also: How To Do A Great Phone Interview

Can You Explain The Advantages Of Plcs Over Conventional Relay

The interviewer might ask this question to determine if you have in-depth knowledge about relays and PLCs. PLCs are steadily replacing mechanical relays across several industrial applications due to their various benefits. Understanding the fundamental differences between these components and their way of working can help you elaborate on the distinct advantages of a PLC.

Example:”PLC systems offer increased reliability, accuracy and flexibility compared to a mechanical relay. They are easy to install as they require less wiring and are also easier to maintain than a regular relay. PLCs offer more advanced functions like data gathering, supervisory control and monitoring. Another huge advantage of a PLC over a relay is the reduced cost. As PLCs are less expensive, they help in reducing the system’s overall lifecycle cost.”

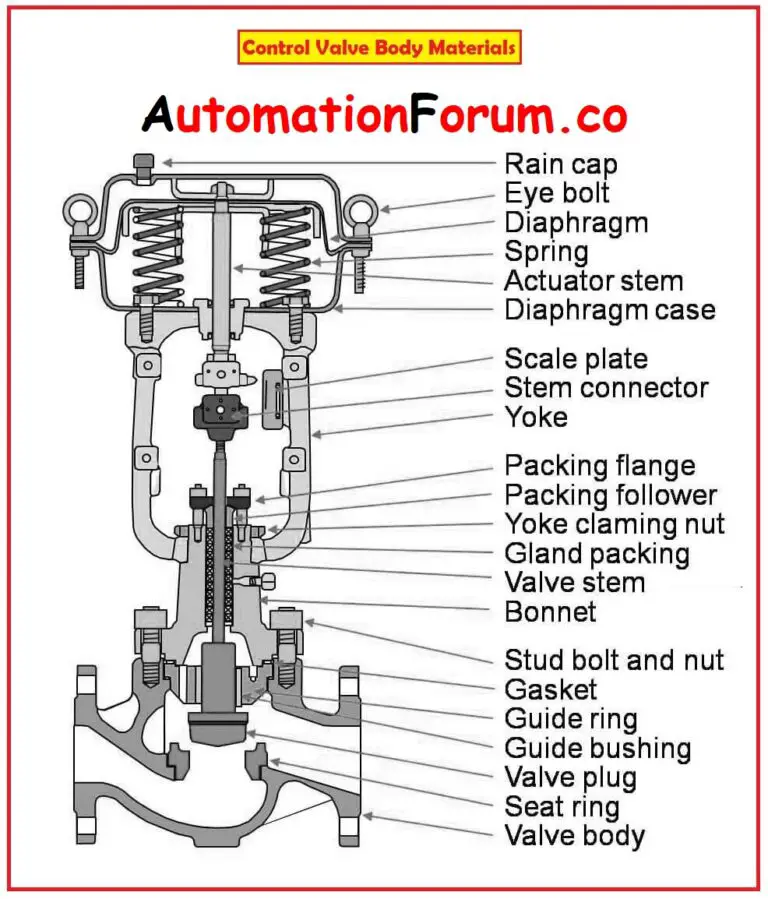

What Is Control Valves

The control valve, commonly named the final control element of control contains a pneumatic device that converts the control signal from the controller in action, regulating the flow.

A control valve is a valve used to control fluid flow by varying the size of the flow passage as directed by a signal from a controller.

This enables the direct control of flow rate and the consequential control of process quantities such as pressure, temperature, and liquid level.

Read Also: Email To Schedule An Interview With Candidate

What Is The Difference Between Plc And Your Personal Computer

The architecture of a PLCs CPU is essentially the same as that of a general-purpose computer however, they are differentiated by some important characteristics. Firstly, unlike machines, PLCs are explicitly designed to survive the harsh industrial conditions

A well-designed PLC can be mounted in an environment with significant amounts of electrical noise, electromagnetic interference, mechanical vibration and humidity-free of condensation